Welds inspection

Overview

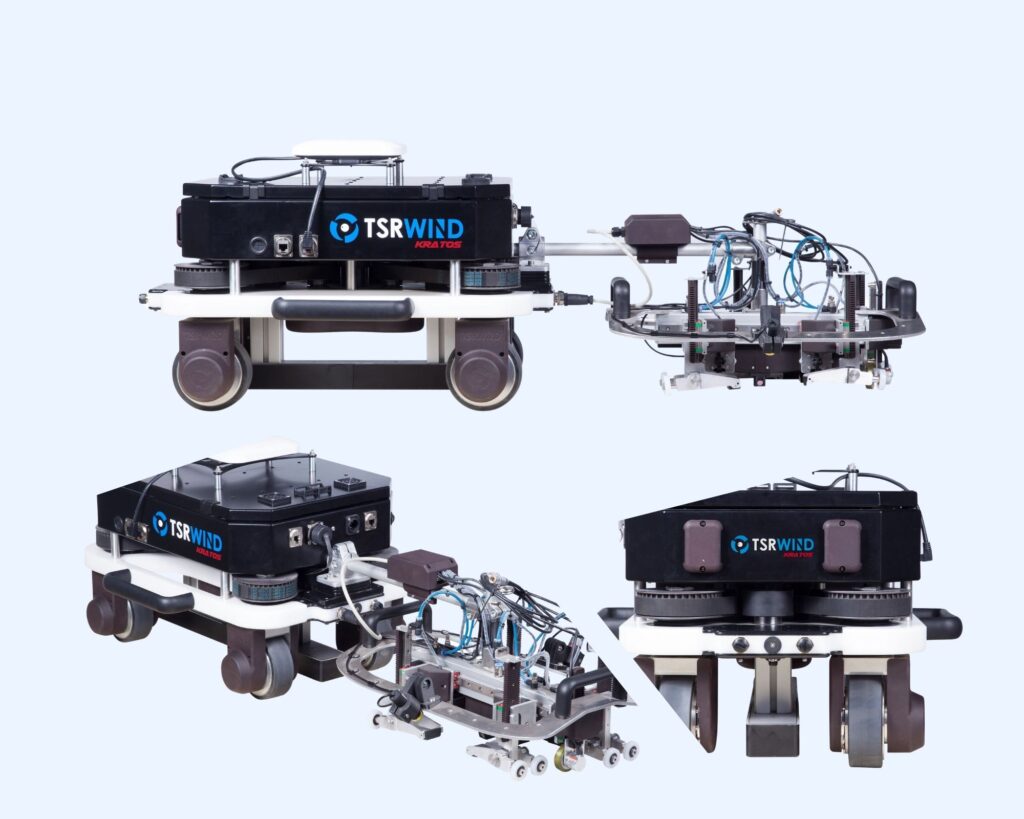

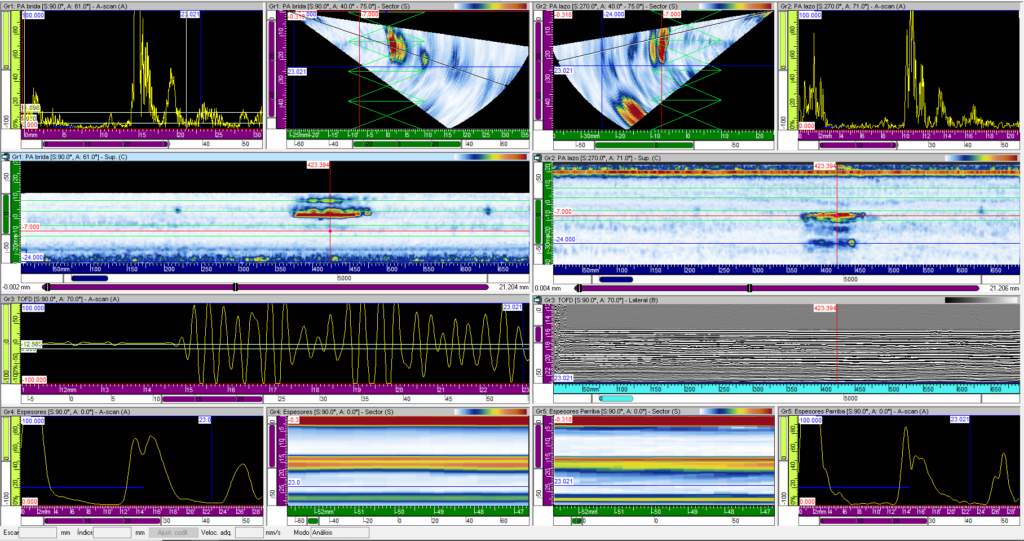

KRATOS uses advanced Phased Array and TOFD ultrasonic technologies to accurately detect both surface and subsurface anomalies in turbine towers.

Report contents

Each inspection concludes with a detailed report including:

- Evidence of anomalies within the weld

- Exact size and location of each finding

- Classification of defect type

- TOFD and Phased Array imaging of all defects

Safety

KRATOS eliminates the need for platform or rope access by enabling inspections to be performed entirely from the ground. This approach significantly reducing working-at-height risks, enhances site safety, and increases inspection efficiency without compromising quality.

Advantages

- Zero worker-at-height risk

- Reduces inspection costs and time

- Captures and records the full length of all welds

- Reliable, high-accuracy results analysed by a certified UT expert

- Provides critical insights to support turbine life extension

- Minimized set-up and deployment time